Design Advanced Professional

Design Advanced Professional

- Creo Parametric*

Collaboration Extensions for Inventor and SolidWorks

Simulation Elite (Linear Structural Analysis)

Flexible Modeling Extension (FMX)

Design Exploration Extension (DEX)

Piping and Cabling Extension (PCX)

Render Studio Extension

Intelligent Fastener Extension (IFX)

Advanced Framework Extension (AFX)

Human Factors Extension

Human Factors Analysis Extension

Advanced Assembly Extension (AAX)

Prismatic and Multi-Surfaces Milling Extension

Engineering Notebook

Additive Manufacturing Extension (AMX)

Interactive Surface Design Extension II (ISDX II)

Behavioral Modeling Extension (BMX)

Mechanism Dynamics Extension (MDO)

EZ Tolerance Analysis Extension**

GD&T Advisor Extension

Tool Design Extension (TDO)

Expert Moldbase Extension (EMX)

High Speed Milling Advanced Extension**

Layout Extension

Collaboration Extensions for CATIA V4 and V5

Collaboration Extension for NX

Creo Interface for JT

Simulation Extension

Fatigue Advisor Extension

Creo Product Insight Extension

GD&T Advisor Advanced

Production Machining Extension

NC Sheetmetal Extension

Creo Clearance and Creepage Analysis

Advanced Simulation Extension

Complete Machining Extension

Options Modeler Extension

Creo Generative Topology Optimization (GTO)**

Additive Manufacturing Advanced Extension (AMX Adv)

Additional capabilities for Design Advanced Professional:

Create and optimize lattice structures and define printer tray setup:

- Automated creation of 2.5D and 3D lattice structures

- Seamless analysis and optimization of lattice

- Printer tray setup and nesting optimization

Interactive Surface Design

Combine the power of parametric modeling and flexibility of freeform surfacing:

- Combined freeform and technical surfacing in a single environment

- Focus on design aesthetics and shape rather than constraints and parameters

- Design precise curves and surfaces to achieve highly-engineered, manufacturable products

Behavioral Modeling

Optimize geometry to solve for design goals and engineering criteria:

- Automatically solve for design goals

- Create smart models that adapt to change

- Define and track custom measures

Mechanism Dynamics

Analyze and optimize the dynamic performance of mechanism designs:

- Model real-world force, loads and contact types

- Analyze mechanism behavior and reactionary forces

- Seamlessly transfer reaction, gravity and inertial loads to Creo Simulate (Structural Analysis)

Tolerance Analysis

Analyze and understand geometric tolerance stack-up and dimensional variation:

- Evaluate the impact of tolerances on the manufacturability of designs

- Identify critical dimensions that contribute to the measure variation

- Automatically generate HTML reports

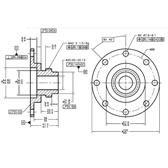

GD&T Advisor

Simplify GD&T creation and improve MBD compliance with latest standards (ASME & ISO):

- Wizard-like dashboard to guide the user in the correct application of GD&T

- Feature-centric view of GD&T

- Advisor Tree – displays messages to inform and guide the user

Tool Design

Accelerate the design of high-quality production mold and cast tooling:

- Easy to use process driven UI for Mold and Cast design

- Automated creation of parting line and parting surface geometry

- Associative design and tooling updates

Expert Moldbase

Automate manual, time-consuming tasks to speed the creation of moldbase tooling:

- 2D process-driven workflow for moldbase design and detailing

- Customizable “smart” mold component library

- Automatic ejector pin, waterline, and fittings functions, automatic runners and waterline checks

Mold Machining

Deliver rapid production of mold, die, electrode and prototype parts:

- 3-axis trajectory milling

- Comprehensive holemaking

- High speed 3-axis machining powered by ModuleWorks

Creo Layout

Maximize productivity using integral 2D layout and 3D detailed design:

- Easily create from scratch or edit existing information

- Directly utilize 2D data to speed the creation of 3D design

- Implement changes driven from 2D layout information

Multi-CAD Collaboration

Seamlessly integrate and work with data from SolidWorks and Autodesk Inventor:

- Collaboration for SolidWorks (Open, Update and Save As native SolidWorks files)

- Collaboration for Autodesk Inventor (automatically detect and update Inventor data)

Piping & Cabling Design

Create and optimize routings for cost, manufacturability and service:

- Automated routing referencing 2D Schematic logic

- Easily visualize and edit using drag handles and on-the-fly editing

- Ability to compare/validate 3D data against 2D schematic logic

Rendering (powered by Luxion's Keyshot)

Produce photorealistic images for design review, marketing collateral, and product packaging:

- Real-time Raytracing powered by Luxion Keyshot

- Enhanced lighting with High Dynamic Range Image (HDRI) support

- Standard library of over 200 predefined materials types

Design Exploration

Rapidly create and explore concepts and modeling alternatives:

- Explore design changes safely without risking original designs or committing to any change

- Simultaneously develop different ideas and evaluate all options before making decisions

- Eliminate manual data duplication and session clean-up for loading and reloading different versions

Fastener Design

Automate fastener geometry creation and hardware assembly:

- Automate the creation of holes and assembly fasteners

- Access to standard libraries (ANSI, DIN, JIS)

Advanced Framework Design

Speed design and improve the accuracy of structural framework assemblies:

- Fully integrated modeling, framework design and analysis

- Comprehensive and customizable libraries of profiles, joints, connections and equipment

- Automated beam placement and creation of framework geometry (e.g., joints, connections)

Legacy Data Migration

Support legacy data migration and CAD consolidation efforts:

- Legacy Drawing Associator (LDA) – automatically connects parametric models to imported legacy data

- Relink model and drawing to provide associativity (update) and association when checked into Windchill PDMLink

- Annotation Convertor (AC) – Automatically convert drawing dimensions and notes to 3D annotations

Human Factors Design

Validate and optimize products for human interaction:

- Quickly insert and customize digital human models to prevent ergonomic mismatches and reduce prototype costs

- Easily manipulate manikins

- Visualize human reach and vision

Core Simulation Capabilities

Enhance your product design with Simulation & Analysis:

- Static Structural Analysis

- Simulate Parts and Assemblies

- Simulate Solid, Beams, Shells, Masses, Springs

Advanced Assembly

Facilitate and support your concurrent design and development:

- Data Sharing and Distribution

- Reference Control

- Change Propagation

Prismatic and Multi-Surface Milling

Achieve the highest quality, highest precision machining in the fastest time possible:

- Multi-Surface 3-axis milling with 4- and 5-axis positioning

- High speed machining (for rapid prototyping and manufacturing)

- Automatic change propagation and associative update of NC toolpaths